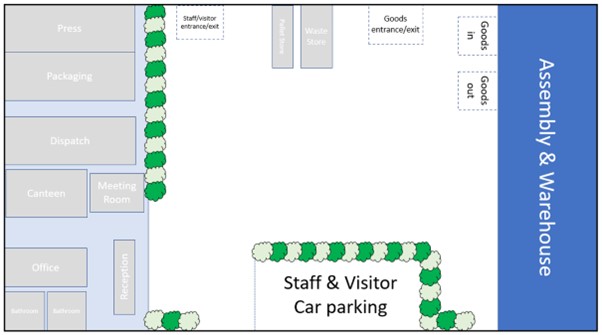

Resource mapping

It is often difficult to grasp the nature, scale, and impact of the resources your organization uses. Therefore, there are suggested techniques for identifying opportunities to make savings, including a process known as resource mapping. This involves undertaking an inspection of your facilities (also called a site walk-around) and making notes and mapping elements such as:

- The types, volumes, and costs of resources your organization uses. Remember this includes materials, any energy (in the form of electricity or fossil fuels used within processes), and water consumption.

- Where these resources are used. What are the primary resources being used in different areas? How does this differ across a site and between sites?

- The types, volumes, and costs of the wastes produced in your daily activities. What kinds of solid and liquid wastes are being produced? This should also include any wasted heat or off-cuts of materials involved in manufacturing.

- Where do the wastes occur? What are the larger waste volumes, and how does this vary across the site? If multiple sites are operated with similar functions, is there significant variance between them in terms of waste generated?

- Why are these resources being used, and why waste occurs? What is the benefit of using the resources identified, and why is waste produced? Does it provide benefits to the organization?

You can

download the Site Walk-Around Checklist below,

which suggests what to look out for during your inspection of the site.

Before you start the site walk-around, consider the following:

- Accessibility - do you need keys or assistance to access any areas?

- Are any areas only used at particular times of the week or month, or processes that rotate over time? E.g., for different product cycles? You will want to record when they are operating and consider visiting the location when it is being used and when it is not in use.

- Do you need a Health & Safety / Risk assessment? This should be discussed with facilities managers and individuals in charge of health and safety.

- Let people know when your walk-around will happen and why you are doing it. Reassure them that it’s not a check on their performance and that they should proceed as usual.

- Consider the people who will know critical resource use and waste generation in the areas you will be visiting. Book time with them or ensure they will be present during the walk-around. This can help you to understand why materials are used, and waste is produced within an area.

This template has been made available so you can develop your own site checklist to help support assessment of your organization's site-based resource efficiency. The template is in a docx format, so that it can be easily edited in Microsoft Word, Google Docs or other similar document editors - you can add your own logo and format the document as you need. Elements highlighted in yellow are recommended as minimum elements to update.

This document provides an example with mock branding added, so you can see how a final layout might look.