When replacing a boiler, it is worth considering fuel

switching. This provides the opportunity to move from expensive fuels, such as

oil, LPG, or electricity, to less expensive and more environmentally friendly

forms of heating such as biomass or heat pumps. Fuel switching is particularly

relevant to businesses that are not connected to the gas grid.

Ground

source heat pumps

Ground source heat pumps take low-grad energy from the

ground and convert it to higher grade energy for use in heating by means of a

heat pump. It is important to recognise that the pump is powered by

electricity, so this is still an electrical form of heating, though much more

efficient than electrical resistance heating (such as storage heaters or bar

fires).

In addition to high installation costs, there are various

constraints:

·

Ground source heat pumps work

best where there is a low-temperature distribution system, such as underfloor

heating and where the building is well insulated.

·

Space is required outside for a

collector loop- this could be a horizontal or vertical loop, depending on space

availability and ground conditions.

It is worth noting that, under the Biden administration, the

Department of Energy has announced a $250 million funding opportunity to

advance heat pump manufacturing in the U.S. In theory, this should decrease the

upfront cost of the technology over time.

Air

source heat pumps

In the same way that a refrigerator extracts heat from its

interior, an air source heat pump extract heat from the outside air. This heat

can then be used to heat radiators, warm air convectors, hot water, or

underfloor heating systems. These pumps can extract heat from air even when the

temperature is as low as 5° F. Like ground source heat pumps, air pumps are

powered by electricity, meaning this is still an electrical form of heating.

In addition to higher installation costs, various

constraints exist with air source heat pumps as well:

·

Air source heat pumps work best

where there is a low-temperature distribution system, such as underfloor

heating and where the building is well insulated.

·

Outside space is required for

the external condenser unit (similar size to an air conditioning unit). These

units can be loud and may also blow out colder air.

Biomass

boilers

Biomass boilers can be a good option if your facility has a

high and constant demand for heat (likely in old buildings that are in constant

use) and if there is a reliable source of biomass fuel. Facilities that have a

need for continuous heating can justify the high installation cost of a biomass

boiler.

Because biomass is considered a renewable energy source, the

carbon emissions from this type of heating will be very low, if the feedstock

is sustainably produced and not transported at a great distance.

All forms of renewable or low-carbon heating can have a

positive impact on a company’s ESG (environment, social, governance)

reputation. It can also be used to encourage employees to become more aware of

sustainability issues at work or at home.

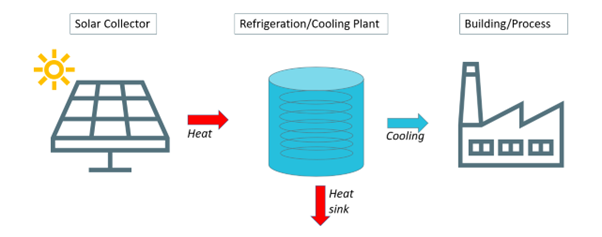

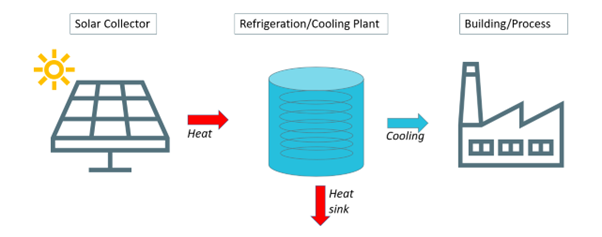

Solar

Cooling

Solar cooling is a technology that allows heat from the sun

to be used for refrigeration and cooling equipment. Solar energy is collected

(usually by solar panels) and then is used to produce chilled water or air for

buildings’ air conditioning systems. The process can be seen in the diagram

below:

There is likely a higher up-front cost for a solar cooling

system than a traditional HVAC system, but it can be less expensive in the

long-term as it does not rely on purchased electricity. Additionally, many

countries offer rebates or tax incentives to support businesses looking to

invest in solar photovoltaics.

Renewable

Electricity

If specific renewable systems (e.g., solar

cooling or ground source heat pumps) are not a financially viable option for

your organization, consider looking to your energy provider. Many energy

providers now allow customers to opt for energy from renewables. If this is not

an option at your current provider, consider switching providers. This switch

will help you to decrease your carbon emissions.